Advanced Labelling Systems Ltd have been building industrial label application machinery & producing printed self-adhesive labels at our Oxfordshire base since 1997.

Label Applicators

Label Applicators

Label applicators apply self-adhesive labels consistently to products in large quantities, with high accuracy and reliability. They can be mounted above or to the side and even upside-down, underneath a conveyor, to achieve the best labelling position.

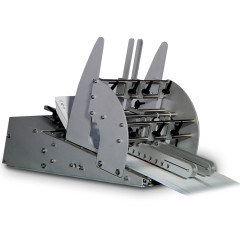

Feeders

Feeders

Friction feeders provide for a wide variety of applications within packaging lines to feed coupons, cards, promotional items, bottle hangers, sheets, sachets, 2, 3 and 4 side sachets and many more!

Print & Apply

Print & Apply

A print and apply labeller automatically prints the required variable information onto a label, such as the product description, expiry dates, batch numbers and barcodes and then applies the label to the product - all in one machine.

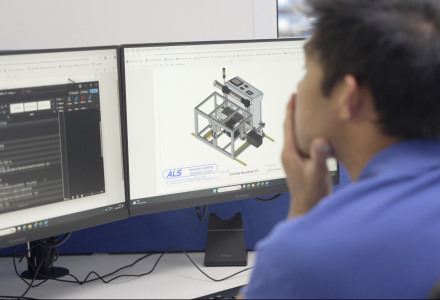

Standard Solutions

Standard Solutions

We offer a range of complete machines for standard applications which have been designed with many years of labelling expertise. If you need something a little more bespoke, then our design team are on hand to create a custom machine to suit your requirements.

Printers & Coders

Printers & Coders

A range of compact and heavy-duty barcode label printers and coders, designed for fast and reliable label printing in production areas and logistics/warehouse environments.

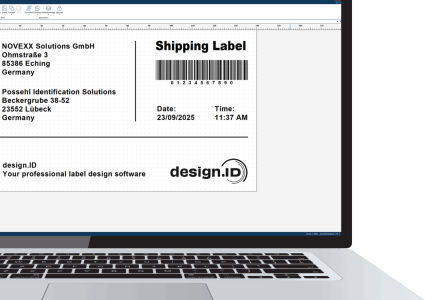

Labelling Software

Labelling Software

Industrial labelling software with 100's of built-in printer drivers to get the most out of your label printer, coder and print & apply labelling equipment.

Ribbons

Ribbons

The best doesn't have to cost the most! As part of the huge Possehl Identification Solutions Group, we buy in bulk from the top material suppliers & convert labels in the UK, so you get high-quality, consistent results from your printing, coding & label application equipment.

Labels

Labels

The best doesn't have to cost the most! As part of the huge Possehl Identification Solutions Group, we buy in bulk from the top material suppliers & convert labels in the UK, so you get high-quality, consistent results from your printing, coding & label application equipment.