Automatic de-nesting machine for trays, containers and lids, which picks products from a stack and places them on a packaging line

The Etipack Clippy De-nester machine is a pick-and-place device designed to separate thermoformed trays and lids from a stack using a vacuum suction mechanism. Stacked product, such as; lids, trays, pots or tubs, are picked from a loading stacker and placed horizontally onto the packaging line.

This de-nester is equipped with a double loading stack, to load 2 rows of products and increase production speed; upon request it is possible to add more loading stacks for even higher production needs.

The programming keypad allows the operator to set speed and control functions in a user-friendly manner, such as; automatic speed adjustment, multiple product distribution, control of missing picking with automatic stop.

Features of the de-nester

- Base support structure

- Double loading stack (more loading stack upon request)

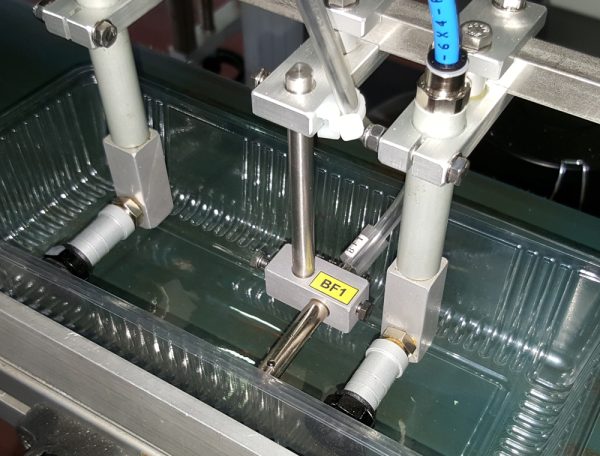

- Mechanical device with vacuum pad for horizontal positioning

- Control on missed picking

- Venturi vacuum pump

- Safeguards on kinematic

- Separate control box (remote terminal up to 3m) with integrated PLC

- Separate control panel (remote up to 3m)

- Brushless motor

Ancillary devices

- Start for tray picking and placing

- Control on minimum load

- Programming keyboard

- Vacuum pump (according to products)