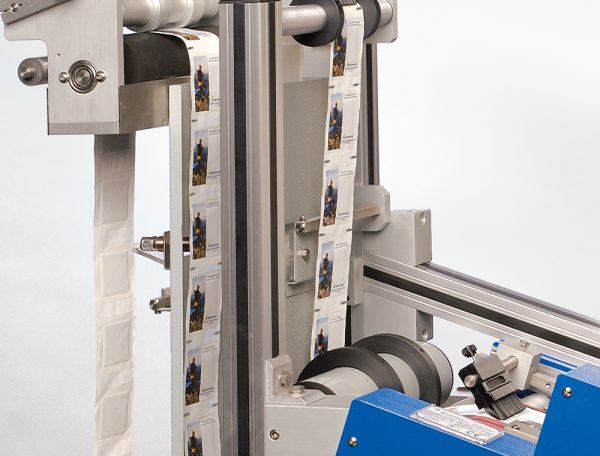

The Etipack roll friction feeder Whizzy Roll is specifically designed to feed coupons, header cards etc, from a roll format and to cut them into individual items.

The roll feeder provides for full automatic unrolling, cutting and feeding into the packaging line with a speed up to 150 pcs/min of different materials with a thickness up to 2mm, such as paper, cartons, flexible packaging, plastic packaging materials, cleaning pads, food absorbent pads and more!

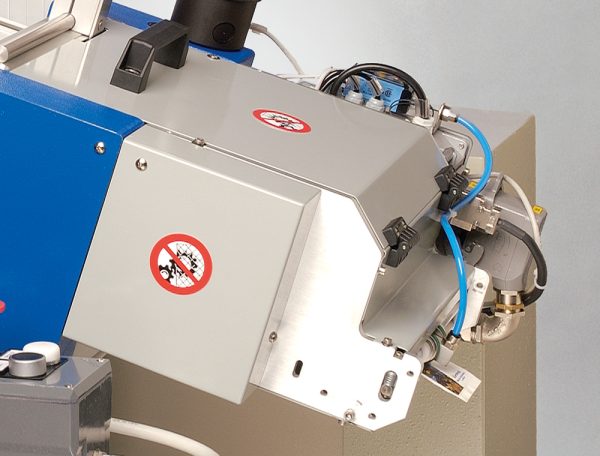

The machine is equipped with an orbiter cutter ensuring a clean and precise cut to proper size.

Cutting size is operated from a keyboard by setting length paraments, in order to vary pitch length according to actual manufacturing needs.

Features of the feeder

- Feeding from roll format

- Mechanic unwinder

- Brushless drawing with step movement by stop control

- Orbiter cutter with saw-toothed and brushless motor actioning

- Stop sensor on product distribution

- Separate control box (remote terminal up to 3 m) with integrated PLC

- Separate control panel (remote up to 3 m)

- Brushless motor

- Programming keyboard

Ancillary devices

- Base support structure

- Customized support structure