Tandem Mode Feature in XLS Labellers Reduces Downtime

Find out how to boost your line‘s productivity using the two XLS Label applicators in tandem mode, while reducing the risk of production downtime.

The Challenge

In manufacturing, maximum output is key. Companies are continually looking for ways to keep up with the demands of our consumer led world and they do this by investing in high performance production lines. Nothing strikes more fear into the life of a Production Manager than the sight of flashing red lights and the sound of machine alarms on a production floor. Unplanned downtime on a production line is a costly and frustrating business. It can result in unproductive employees, missed customer deadlines, overtime for technicians as well as incurring the cost of shipping in urgent parts, all of which can have a damaging effect on your company’s reputation.

The Solution

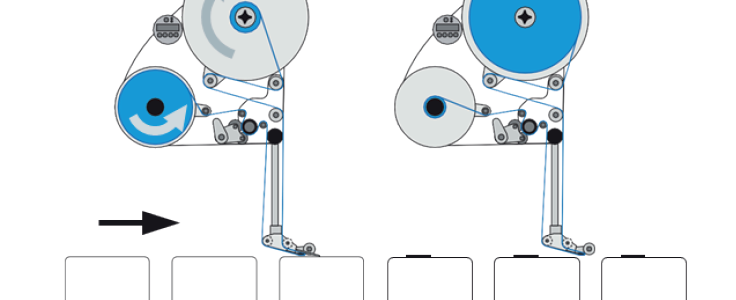

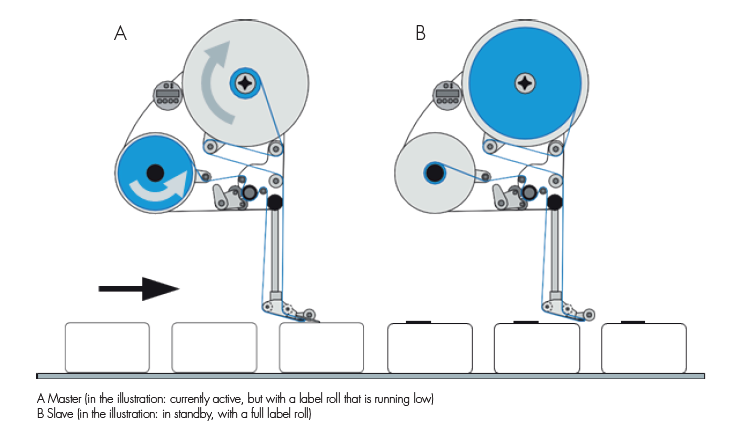

Here is where we can offer peace of mind. Our XLS label applicators can be operated in tandem mode, which means two labellers are arranged behind one another. Only one of the labellers is in operation at a time. The other remains in standby, ready to leap into action when required. If the active labeller reports the end of the label roll or a malfunction occurs, it shuts down. The other labeller immediately takes over the task of labelling. During the automatic switch-over from one machine to the other, the distance between the two machines and their arrangement are taken into consideration. This way, no product remains unlabelled. The operator now has time to either reload with new label material or to eliminate minor malfunctions.

Click this link to read more about the amazing features of the XLS label applicators